ABOUT NEWSKY

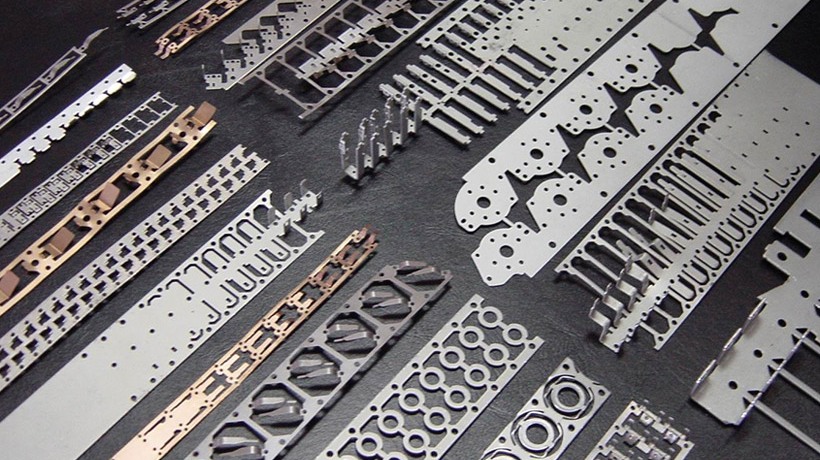

At Newsky, there are more than 50 presses and injection machine rated at 60 up to 400 tons and high precision processing equipment more than 36 sets. our capabilities include stamping die, injection mold, Metal stamping and precision parts processing. We have the capacity to make small parts and parts size large to 1000mm.

Our manufacturing plant contains a well-equipped machining shop and die shop, which allows us to build all necessary tooling in-house, Makino V33 machining center, Makino EDM and wire-cut machine, NC grinder machine and so on, tooling parts dimension tolerance can be up to ±0.001mm and meet the high precision requirements.

Newsky utilizes CMMs and other more than 10 sets devices for dimensional inspection, our quality assurance program is ISO certified. In addition to printer components, furniture components, medical equipment, we also produce sensor components, pachinko components, and other OEM services.

In addition, we provide rapid fixture and planetary gear reducer products for customer, Of course, provide ODM service for you.

Our experience spans many markets with stringent quality requirements, and we comply with an extensive range of industry standards. To learn more about our tooling make and metal stamping capabilities, contact us directly.